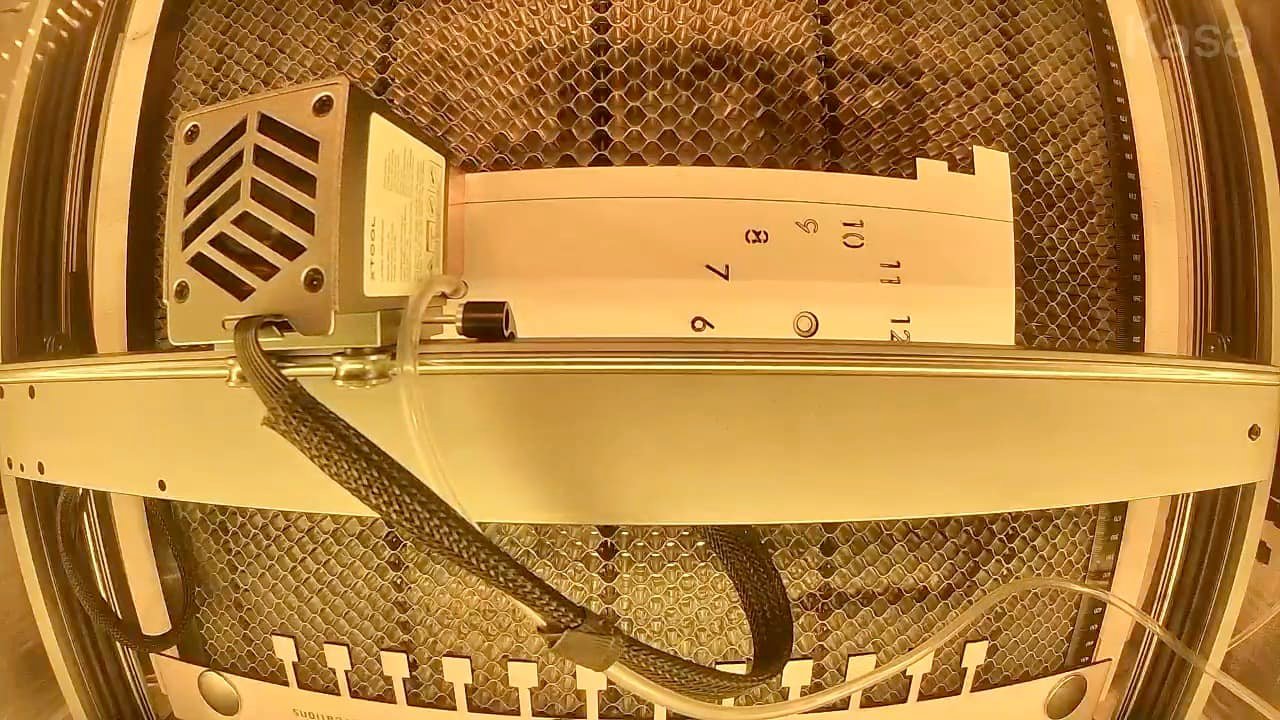

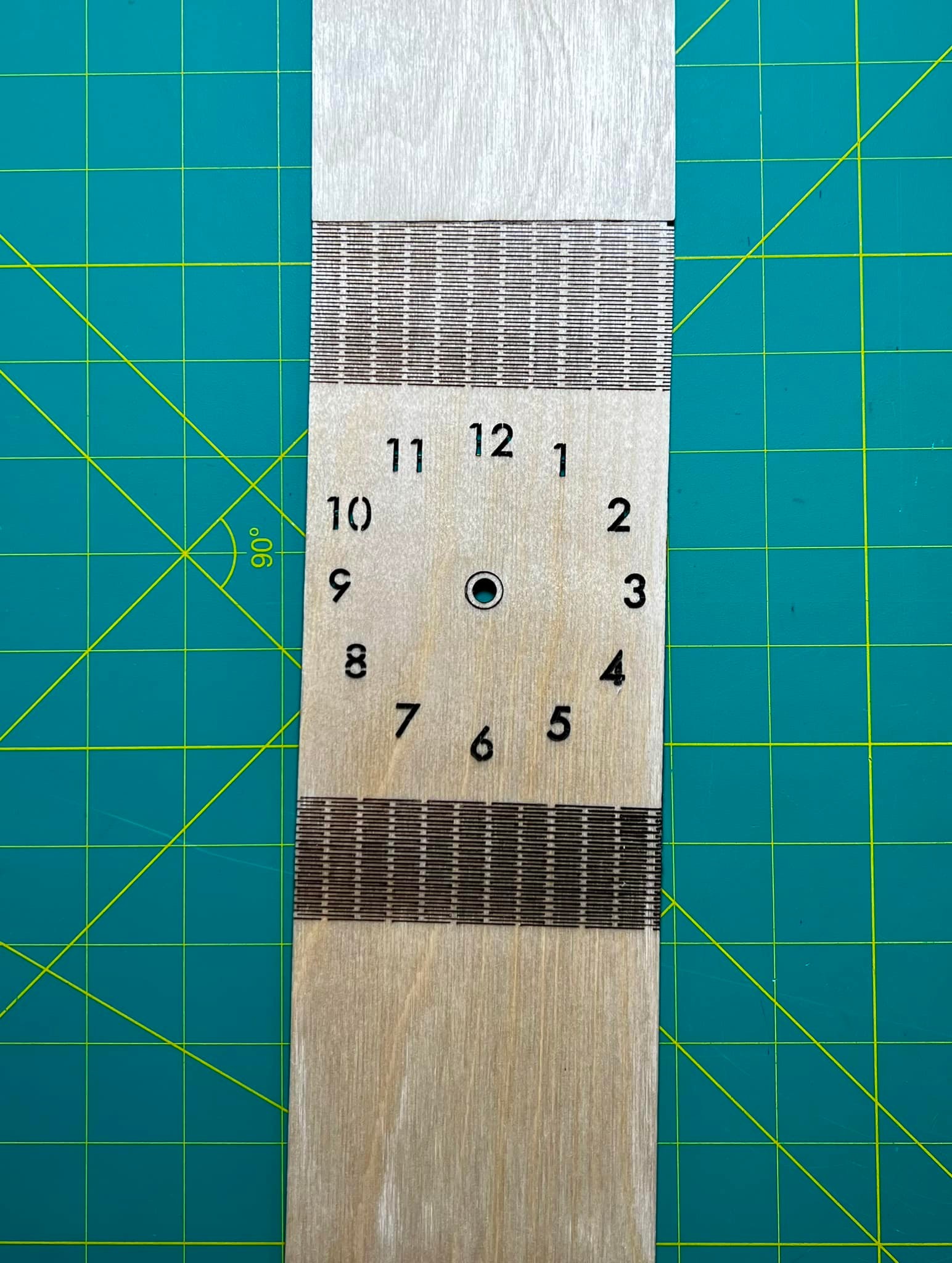

To create a custom-made wooden clock with flexible hinges using a laser engraver, and stained and finished with polyurethane, you can follow these general steps:

Remember to take your time and use caution when working with tools and machines, and to wear appropriate safety gear, such as eye protection and gloves. Creating a custom-made wooden clock with a laser engraver can be an exciting and creative project, and the sleek, precise design of the laser engraver can contribute to an exceptional final product.